SURVIVAL THROUGH QUALITY

PRODUCT CENTER

-

Pulse dust collector

-

Mine dust collector

-

Boiler dust collector

-

Metallurgical dust collector

-

Carbon plant dust collector

-

Chemical dust collector

-

Rubber dust collector

-

Woodworking dust collector

-

Single machine dust collector

-

Static electricity Dust collector

-

Cyclone dust collector

-

Wet dust collector

-

Filter cartridge dust collector

-

Insert valve (gate valve)

-

Ventilation butterfly valve (cold air valve)

-

Spiral conveyor (auger)

-

Scraper conveyor

-

Dust humidifier

-

Bucket elevator

-

Ash discharge valve

-

Material Handling Equipment

-

Wet scrubber

-

Dust collector

-

Dust removal filter bag

-

Dust removal bag cage

-

Polishing platform

-

Waste gas treatment equipment

-

Electric control cabinet

-

Fan

-

Smoke welding machine

-

Liquid level switch

-

Dust removal filter element

-

Aeration cushion

-

Sweeper

-

Dust suppression device

-

Solenoid valve

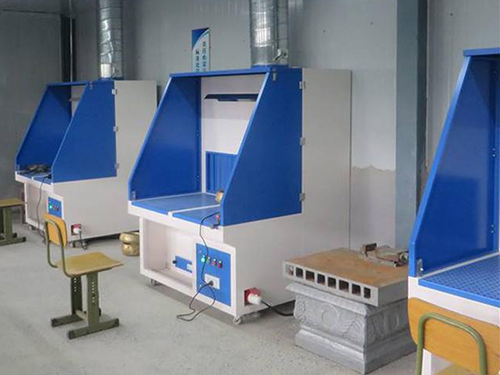

Polishing platform

The polishing platform is a specialized device composed of pipes, fans, and filters used in woodworking workshops, polishing workshops, and paint workshops to remove sawdust, paint dust, and other particles generated during the processing.

Polishing platform dust removal principle:

Woodworking dust removal requires three devices: pipeline system, fan system, and filtration system. In these three systems, the structure and function of different configurations are different, but the basic principles are the same, just like wearing a mask. The pipeline is connected to the woodworking machinery and filtration system, and the operation of the fan generates negative pressure dust suction in the pipeline. The main aspects are the configuration of the fan and the performance of the filter bag.

The configuration of the fan is calculated based on the arrangement of the number of machines in the production workshop, which requires professional personnel to calculate the configuration so that the air volume of each machine's filtering interface is consistent in order to effectively remove dust. Dust removal filter bags should be selected according to different environments, and the properties of dust generated in different woodworking workshops are different.

The airflow containing sawdust particles is transported by a fan to the guide chamber of the bag filter. The airflow velocity decreases under the action of the guide plate, and heavier sawdust particles fall into the ash chamber under the action of gravity. Other lighter and finer dust is adsorbed on the outer surface of the filter bag along with the airflow direction. After being filtered by the bag, clean gas enters the exhaust chamber and is discharged outside. As the filtration condition continues, more and more dust accumulates on the outer surface of the filter bag, which increases the operating resistance of the system and reduces the dust removal efficiency.